Understanding Unmanned Systems (UAS)

Unmanned Systems (UAS) represent a transformative leap in technology, merging the physical and digital worlds to perform tasks without direct human intervention. These systems are not just remote-controlled toys; they are sophisticated platforms possessing a high degree of autonomy and independent decision-making capabilities. At their core, they are the product of the convergence of Artificial Intelligence (AI), advanced robotics, and real-time control/decision-making systems. This synergy allows them to perceive their environment, make informed decisions, and execute complex missions with remarkable precision.

The scope of Unmanned Systems is vast and continually expanding, encompassing a wide array of vehicles:

Unmanned Aerial Vehicles (UAVs): From aerial photography and agricultural spraying to search and rescue operations.

Flying Cars (eVTOL): The next frontier in urban air mobility, promising to revolutionize transportation.

Unmanned Ground Vehicles (UGVs): Including autonomous delivery robots, industrial logistics carriers, and even robotic lawn mowers.

Unmanned Surface Vessels (USVs): Used for oceanographic survey, environmental monitoring, and port security.

Unmanned Underwater Vehicles (UUVs): Deployed for underwater exploration, pipeline inspection, and marine research.

The Heart of the System

The CUAV Intelligent Controller serves as the central nervous system and a critical core component for all these unmanned platforms. It is the robust, versatile brain that translates sensor data into intelligent action. Its broad compatibility ensures it can power and manage a diverse range of vehicles, including UAVs, UGVs, USVs, and UUVs, providing a unified hardware foundation for innovation.

Deconstructing an Unmanned System: A Deep Dive into Assembling a Multirotor UAV

To truly understand how these systems come to life, let’s walk through the process of assembling a fundamental platform: a 4kg quadcopter UAV. This example provides a practical framework for understanding the core components and their integration.

What is a Quadcopter?

A quadcopter (or four-axis drone) is a type of rotorcraft that generates lift and controls its movement using four independent rotors. By precisely varying the speed of each rotor, it can achieve stable hover, vertical takeoff and landing (VTOL), and agile flight in any direction.

Step 1: Comprehensive Hardware Preparation

Sourcing the right components is the first critical step. Each part plays a vital role in the system’s overall performance, reliability, and safety.

Controller (x1): This is the flight computer. The CUAV Intelligent Controller, for instance, runs complex algorithms to stabilize the aircraft and execute flight plans.

GPS Module (x1): Provides global positioning and essential navigation data, enabling autonomous flight modes and return-to-home functions.

3510 (360KV) Motor (x4): These brushless motors convert electrical energy into rotational force. The KV rating indicates RPM per volt; a lower KV, like 360, is ideal for larger propellers and heavier payloads on a 6S battery.

40A Electronic Speed Controller (ESC) (x4): Each ESC acts as a sophisticated middleman, receiving commands from the autopilot and rapidly adjusting the power delivered to each motor.

16-inch Propeller (x2 pairs): Propellers generate thrust. You need two pairs: two Clockwise (CW) and two Counter-Clockwise (CCW) to balance the torque and allow for stable flight.

6S (12000mAh) Lithium Polymer (LiPo) Battery (x1): This is the power source. A “6S” configuration means it has 6 cells, providing a nominal voltage of 22.2V. The 12000mAh capacity determines the flight endurance.

Power Distribution Board (PDB) (x1): This board safely distributes power from the main battery to the ESCs and other components like the autopilot and peripherals.

Various Cables and Connectors (xN): High-quality wiring is crucial for reliable power and data transmission. Always use wires with adequate gauge to handle the expected current.

Step 2: System Integration and Connection

With all components ready, the next phase is mechanical assembly and electrical integration. This involves securely mounting the frame, motors, and all electronics, ensuring proper vibration isolation for sensitive components like the autopilot and GPS.

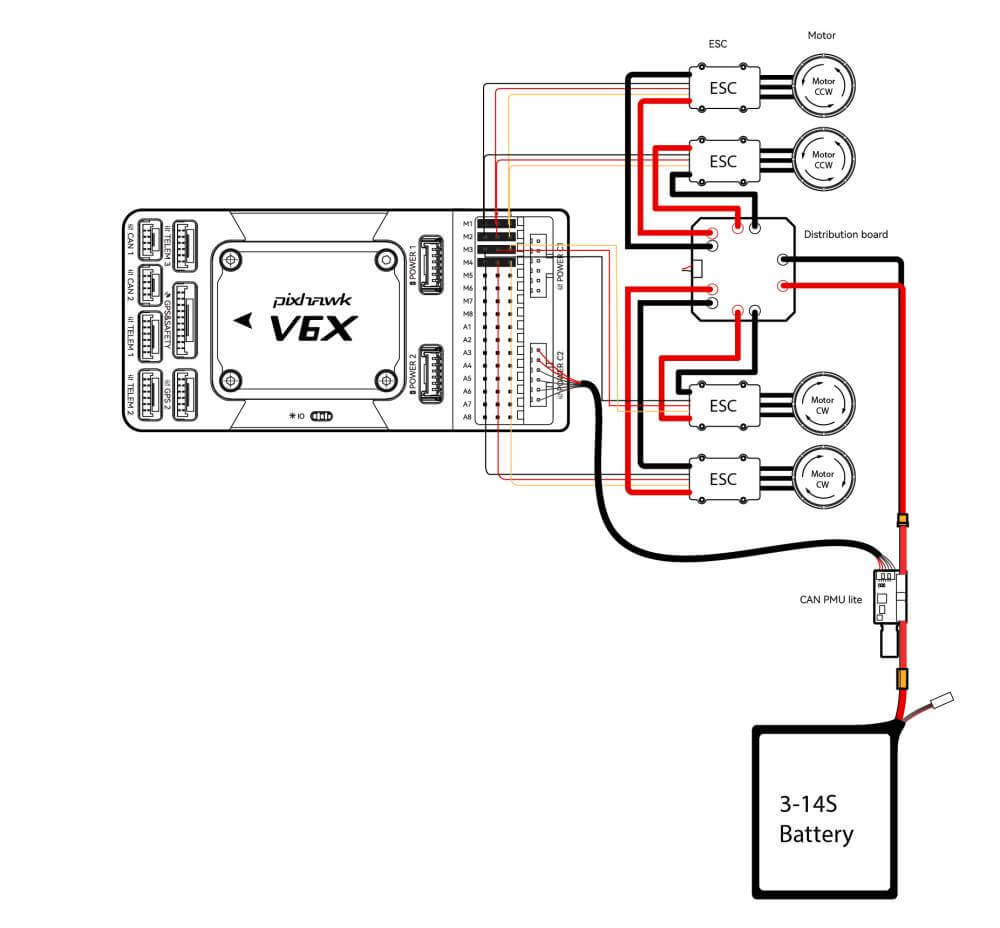

A clear understanding of the system’s architecture is essential. The diagram below illustrates how the key components interact:

Power System Connection Diagram Placeholder

A simplified system connection diagram showing the flow of power (red) and data (blue) between the battery, PDB, ESCs, motors, autopilot, and peripherals.

The Power System forms a critical loop: Battery -> PDB -> ESCs -> Motors -> Propellers. Any failure in this chain can lead to a catastrophic crash, so soldering and connections must be impeccable.

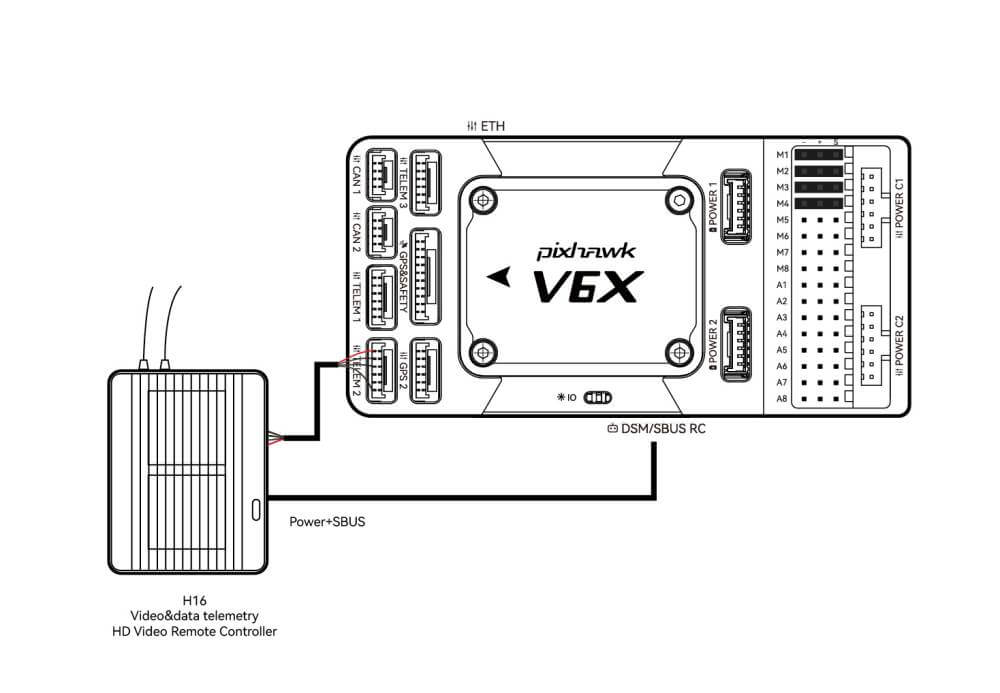

Remote Control Receiver and Telemetry Connection Diagram

The TELEM1/2 ports are for telemetry radio modules, and the SBUS/DSM/PPM port is for the RC receiver.*

Note

The TELEM1 and TELEM2 interfaces connect to telemetry radios for long-distance data transmission and ground station control. The SBUS/DSM/PPM interface connects to the RC receiver for manual pilot commands. The diagram shows a combined RC/Telemetry unit for simplicity.

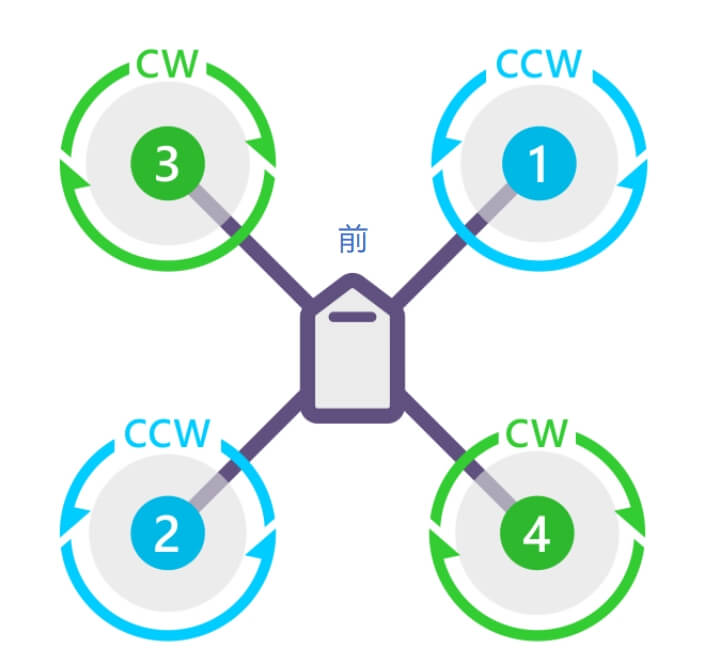

Motor Rotation and Installation Position

Diagram showing motor rotation and propeller installation for an X-type quadcopter.

Note

The above hardware connections are based on an X-type quadcopter frame. The motors and ESCs (M1~M4) are installed at the corresponding positions on the quadcopter. The motor rotation direction is critical: A motor designated for Clockwise (CW) rotation must be fitted with a CW propeller; a motor designated for Counter-Clockwise (CCW) rotation must be fitted with a CCW propeller. This diagonally symmetric, opposite-rotation design counteracts torque effects for stable flight.

Final Result

When all hardware is correctly assembled and the firmware is properly configured, you will have a fully functional intelligent UAV. It will be capable of stable hovering, responding to RC commands, and executing fully autonomous missions planned via the Ground Control Station. This marks your successful first step into the world of unmanned systems development.

A fully assembled and calibrated multirotor UAV performing a flight mission.

The Software Soul: Choosing and Flashing Firmware

The hardware is the body, but the firmware is the soul. The CUAV Intelligent Controller series is agnostic, supporting the two leading open-source autopilot software: ArduPilot and PX4. Your choice depends on your project’s goals, your personal preference, and the specific features you require.

ArduPilot vs. PX4: Choosing Your Autopilot Platform

In-Depth Look at ArduPilot

ArduPilot is one of the most mature and versatile open-source autopilot systems in the world. It is more than just drone software; it’s a flexible, scalable, and high-performance platform supporting over 100 different vehicle types, including traditional drones, unmanned cars and boats, robotic lawnmowers, complex VTOL aircraft, and even submarines.

Key Strengths:

Maturity and Stability: With over a decade of development, its codebase is incredibly robust and well-tested in countless real-world scenarios.

Extensive Vehicle Support: Its unparalleled support for a vast range of platforms makes it ideal for research and commercial applications that involve multiple vehicle types.

Rich Ecosystem: The platform is supported by powerful ground control stations like Mission Planner and QGroundControl, offering deep configuration and mission planning capabilities.

Superior Documentation and Community: ArduPilot’s documentation is extensive, and its large, active user community means help is readily available.

For those entering the world of unmanned systems, especially in academic or multi-role commercial projects, ArduPilot’s maturity and extensive resources make it an ideal and reliable choice.

In-Depth Look at PX4

PX4 is a professional-grade, open-source flight control software stack known for its clean architecture and strong academic and industrial backing. It is the primary flight stack hosted under the Dronecode Foundation, which is supported by major industry players.

Key Strengths:

Modular and Developer-Friendly Architecture: PX4 is designed with developers in mind. Its modular structure, based on a publish-subscribe messaging framework, makes it easier to understand, modify, and extend. This is a significant advantage for custom research and development.

State-of-the-Art Algorithms: It often serves as a testbed for cutting-edge research in flight control and state estimation, integrating the latest academic advancements.

Flexible Licensing (BSD License): This is a critical differentiator for commercial entities. The BSD license allows companies to use, modify, and even incorporate PX4 into proprietary, closed-source commercial products without the obligation to release their own source code.

Strong Academic Roots: Originating from the computer vision and robotics groups at ETH Zurich, PX4 maintains strong ties to academia, making it a preferred choice in university research labs.

For startups and large corporations aiming to build a proprietary product, and for academic institutions focused on robotics research, PX4’s licensing and modular design offer a compelling advantage.

A Crucial Distinction

A common point of confusion arises because PX4 evolved from the hardware project Pixhawk. Many users colloquially refer to any Pixhawk-formatted flight controller as a “PX4.” It’s vital to understand that PX4 is the software, while Pixhawk and CUAV define the hardware standards on which both PX4 and ArduPilot can run.

Safety First!

[WARNING] If you are new to UAV assembly and programming, do not attempt your first flight alone. Always seek guidance from an experienced builder or technician. Conduct initial tests in a wide-open area, away from people and property, and systematically check all systems before arming the motors.

Venturing into Development: Resources and Protocols

The CUAV Smart Controller is built for innovators. By providing a robust hardware foundation that fully supports the ArduPilot and PX4 ecosystems, we empower users to push the boundaries of what’s possible through secondary development.

The MAVLink Protocol: The Language of Drones

Before diving into code, you must understand MAVLink. This is the universal protocol for communication between the autopilot, ground control stations, and any companion computers or onboard APIs. It is a lightweight, header-only messaging library that defines a set of messages for commanding vehicles, receiving telemetry data, and monitoring status. Familiarity with MAVLink is non-negotiable for any serious development work.

Your Development Toolkit

For ArduPilot Developers:

Source Code: ArduPilot GitHub Repository

Development Guide: ArduPilot Official Documentation

Ground Station: Mission Planner Source Code

For PX4 Developers:

Source Code: PX4 Autopilot GitHub Repository

Development Guide: PX4 Official Documentation

Ground Station: QGroundControl Source Code

Our Role in Your Journey

The CUAV Smart Controller is a hardware solution. The software and programs are provided and supported by ArduPilot and PX4. While we are happy to assist users with application and configuration questions within our knowledge, secondary development requires relevant development and self-learning capabilities. Users should consult relevant documentation or hire professional developers for such custom work.