V5 Series Intelligent Controllers: A Deep Dive into the V5+ and V5 NANO

In the rapidly evolving world of unmanned systems, the core flight controller remains the pivotal “brain,” dictating performance, reliability, and capability. CUAV®, in a powerful collaboration with the renowned PX4 open-source autopilot team, introduces the V5 series of smart controllers, setting a new benchmark for advanced, versatile, and robust flight management. This series, adhering strictly to the Pixhawk FMUv5 design standard, offers seamless compatibility with both the PX4 and ArduPilot flight stacks, providing developers, enterprises, and enthusiasts with a superior hardware platform. This comprehensive guide delves into the two flagship variants: the feature-rich V5+ and the compact, space-optimized V5 NANO.

Ⅰ. The V5+ Intelligent Controller

The V5+® represents the pinnacle of CUAV®’s collaboration with the PX4 team. Manufactured by CUAV, it is a high-end, intelligent flight controller designed for demanding applications where performance, expansion, and resilience are non-negotiable. Built upon the proven Pixhawk FMUv5 architecture, it serves as a perfect hardware foundation for both PX4 and ArduPilot firmware, unlocking the full potential of these powerful software ecosystems.

Primary Application Scenarios

The V5+ is engineered as a versatile development board and core controller for a vast array of unmanned systems. It is capable of running custom code or the standard ArduPilot/PX4 programs. Its applicability spans, but is not limited to, the following platforms:

Unmanned Ground Vehicles (UGVs): Including lawn mowers, agricultural sprayers, delivery vehicles, and more.

Unmanned Surface Vessels (USVs): For marine research, surveillance, and delivery.

Unmanned Underwater Vehicles (UUVs): Submersibles for exploration and inspection.

Unmanned Aerial Vehicles (UAVs): All configurations, including helicopters, multirotors, fixed-wing aircraft, and Vertical Take-Off and Landing (VTOL) hybrids.

Robotics: General-purpose robotic platforms requiring precise motion control and sensor fusion.

Key Advantages

Beyond its core functionality, the V5+ boasts several distinct advantages:

- RTK Centimeter-Level Positioning Support: Enables ultra-precise navigation for applications requiring pinpoint accuracy.

- Dual Power Module Interfaces: Provides redundancy and flexible power system design.

- Multi-Color Peripheral LED Ring: Offers clear visual status indication for pre-flight checks and operational feedback.

- Full Aluminum Alloy Enclosure: Ensures excellent durability, heat dissipation, and electromagnetic interference (EMI) shielding.

- Abundant Expansion Interfaces: A wide array of ports facilitates easy integration of numerous peripherals and sensors.

Detailed Hardware Specifications

| Category | Specification |

|---|---|

| Main Processor | STM32F765 (32-bit Arm® Cortex®-M7, 216MHz, 2MB Flash, 512KB RAM) |

| Co-Processor | STM32F100 (32-bit Arm® Cortex®-M3, 24MHz, 8KB SRAM) |

| Sensors | |

| Accelerometer | ICM-20602 / ICM-20689 / BMI055 |

| Gyroscope | ICM-20602 / ICM-20689 / BMI055 |

| Magnetometer (Compass) | IST8310 |

| Barometer | MS5611 |

| External Interfaces | |

| UART Serial Ports | 5 |

| I2C | 4 |

| SPI | 1 |

| CAN Bus | 2 |

| ADC | 2 |

| PWM Output | 8 Standard PWM IOs + 6 Programmable IOs |

| DSM/SBUS/RSSI Input | 1 |

| PPM Input | 1 |

| PM Power Module Input | 2 |

| GPS & Safety Switch Port | 1 |

| Debug/F7 SWD Interface | 1 |

| USB Port | 1 (Type-C) |

| TF Card Slot | 1 |

| Interface Protocols | |

| PPM IN | PPM |

| DSM/SBUS | DSM/SBUS; RSSI: PWM / 3.3V Analog Voltage |

| GPS | NMEA / UBLOX |

| Operating Environment & Physical Params | |

| Power Input Voltage | 4.5 ~ 5.5 V |

| USB Input Voltage | 5V (±0.25V) |

| Servo Rail Voltage | 0 – 36V |

| Operating Temperature | -20 ~ 85 °C |

| Dimensions (L x W x H) | 85.5 x 42 x 33 mm |

| Weight | 91 g |

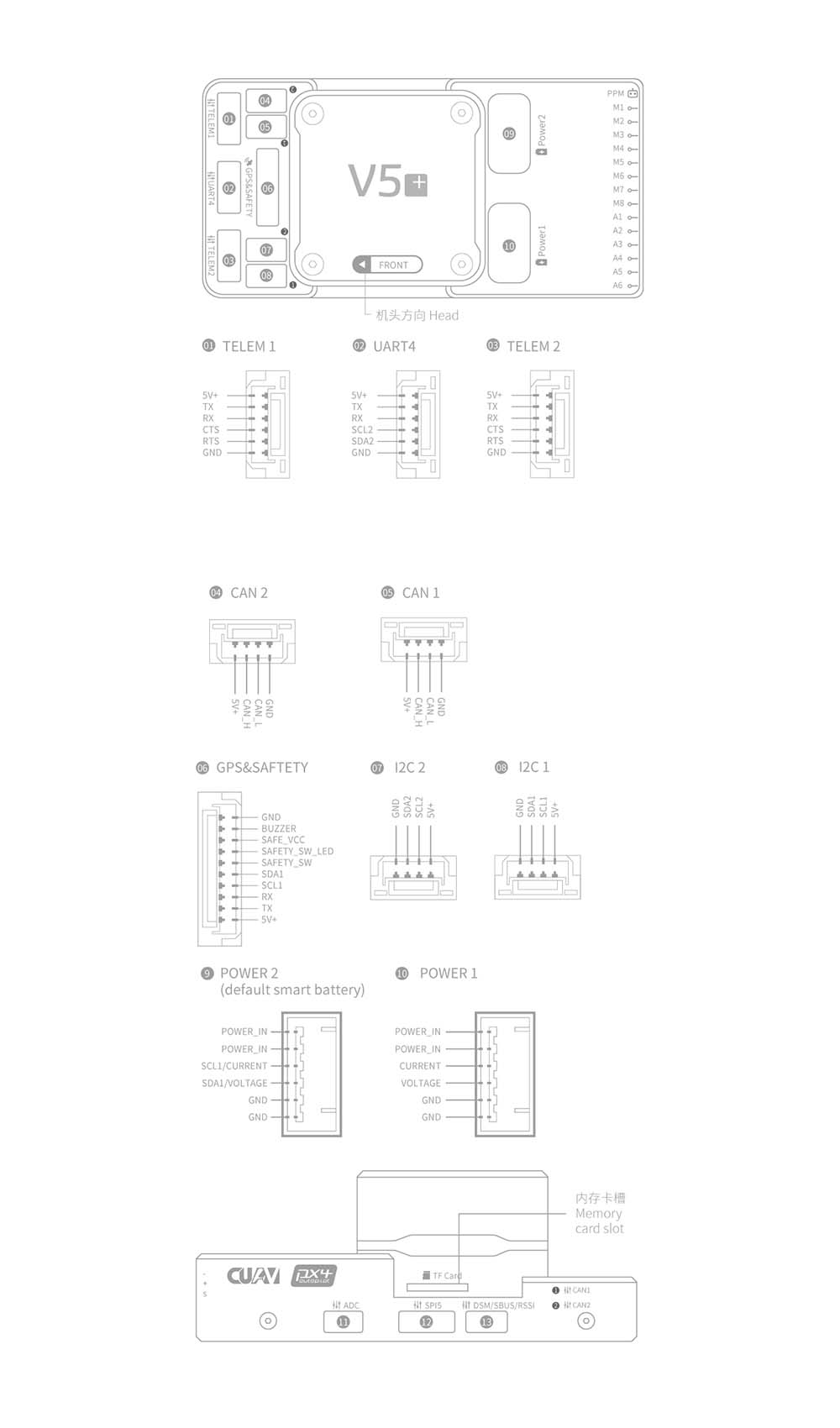

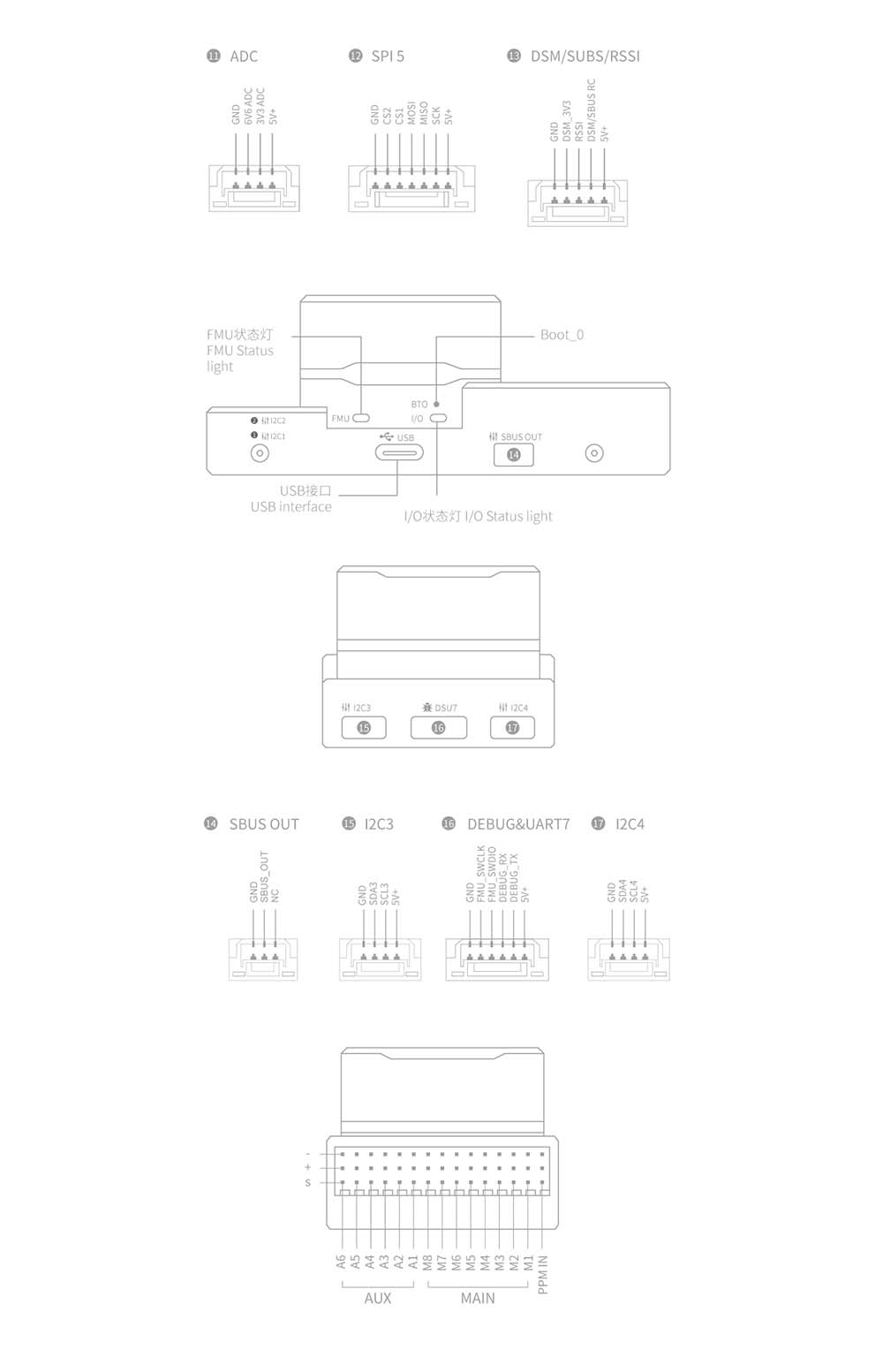

Pinout Definition

Note:

The V5+ smart controller follows the Pixhawk FMUv5 pinout standard. It is different from the Pixhack series definitions. To ensure reliability and prevent damage, it is highly recommended to use the original accessory cables (the green connectors are for the flight controller side).

Important Comments

DUS7 Interface: This is a newly named interface by CUAV. It contains the FMU SWD interface and UART7.

When running PX4 firmware, UART7 is configured as a DEBUG port.

When running ArduPilot firmware, UART7 functions as a general-purpose serial port.

POWER2 Port: By default, this is configured as an I2C Smart Battery interface.

RCIN Port: This port is strictly for powering the receiver. Do not connect any other power source or load to it.

PX4 Firmware Compilation Command

make px4fmu-v5_default upload

ArduPilot Firmware Compilation Command

./waf configure --board CUAVv5./waf copter --upload

Optional Hardware & Accessories

The V5+ can be extended with a wide range of hardware, including:

Airspeed Sensor

Telemetry Radio Module

Rangefinder / Distance Sensor

For more detailed usage information and a comprehensive list of compatible hardware, please refer to the official PX4/ArduPilot documentation for multirotor and fixed-wing optional hardware.

Ⅱ. The V5 Nano Intelligent Controller

The V5 nano® is the answer for applications where space and weight are at a premium, but the powerful feature set of the V5 architecture is still desired. Co-designed by CUAV® and the PX4 team, it packs the core capabilities of the V5+ into a dramatically smaller form factor while maintaining full compatibility with PX4 and ArduPilot firmware.

Primary Application Scenarios

Identical in versatility to the V5+, the V5 NANO serves as a compact, intelligent controller or development board for the same broad spectrum of platforms, including UGVs, USVs, UUVs, UAVs (of all types), and robotics.

Hardware Specifications

| Category | Specification |

|---|---|

| Main Processor | STM32F765 (32-bit Arm® Cortex®-M7, 216MHz, 2MB Flash, 512KB RAM) |

| Sensors | |

| Accelerometer | ICM-20602 / ICM-20689 / BMI055 |

| Gyroscope | ICM-20602 / ICM-20689 / BMI055 |

| Magnetometer (Compass) | IST8310 |

| Barometer | MS5611 |

| Interfaces | |

| UART Serial Ports | 5 |

| I2C | 4 |

| PWM Output | Up to 11 PWM outputs (8 standard + 3 optional PWM/Capture inputs) |

| nARMED* | 1 |

| RC Input Protocols | PPM / SBUS / DSM, etc. |

| RC IN | 1 |

| PPM IN | 1 |

| RSSI Input | PWM or 3.3V Analog Voltage |

| CAN Bus | 2 |

| Current/Voltage Input | 1 |

| Safety Switch | 1 |

| GPS Port | 1 |

| Debug Port | 1 |

| JTAG | 1 |

| USB Port | 1 (Type-C) |

| Operating Environment & Physical Params | |

| PM Input Voltage | 4.5 ~ 5.5 V |

| USB Voltage | 5V (±0.25V) |

| Servo Rail Input | 0 – 36V |

| Operating Temperature | -40 ~ 85 °C |

| Dimensions (L x W x H) | 40.0 x 60.0 x 14.0 mm |

| Weight | 50 g |

Tip: The nARMED interface is only supported in PX4 firmware and is not functional under ArduPilot firmware.

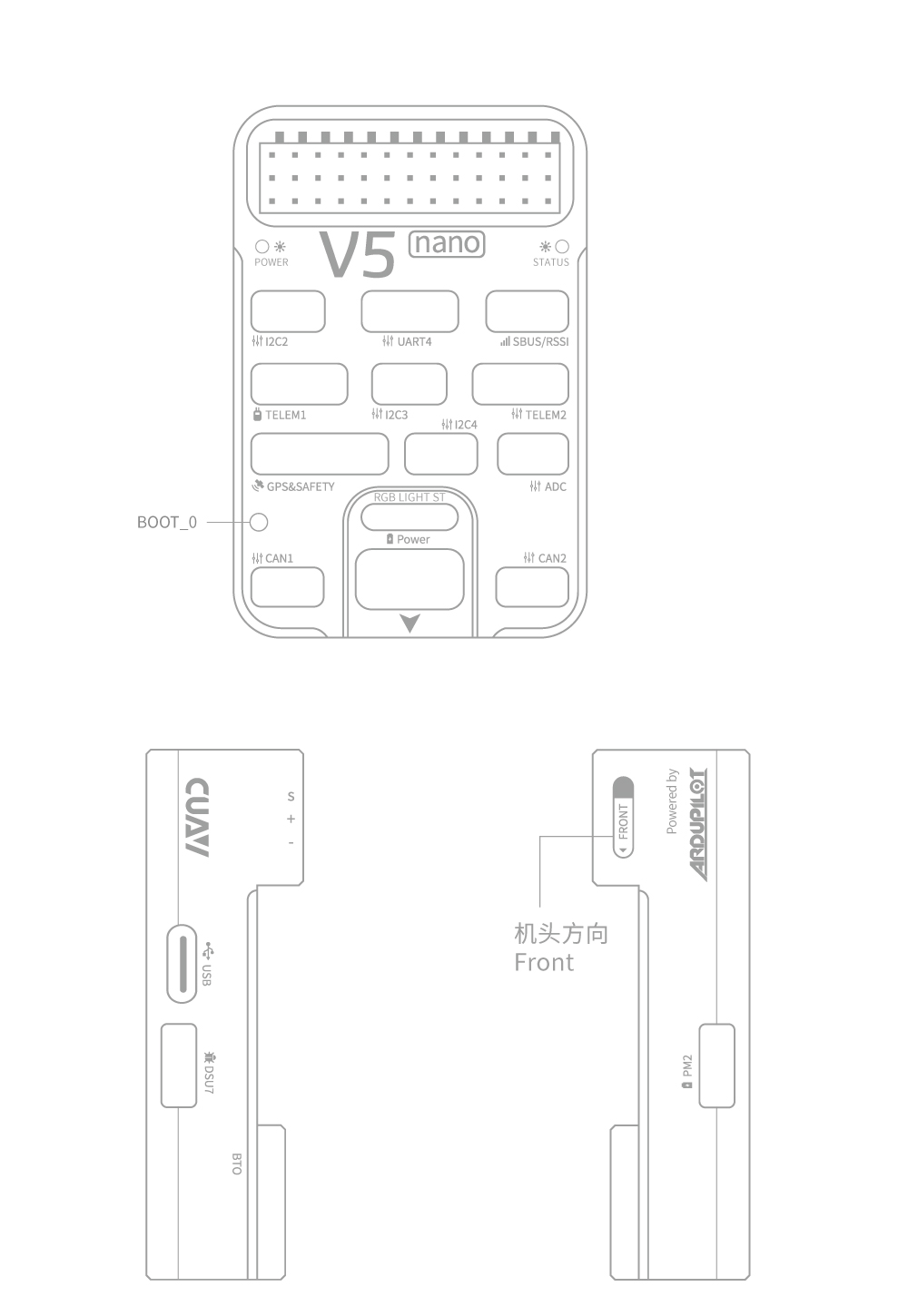

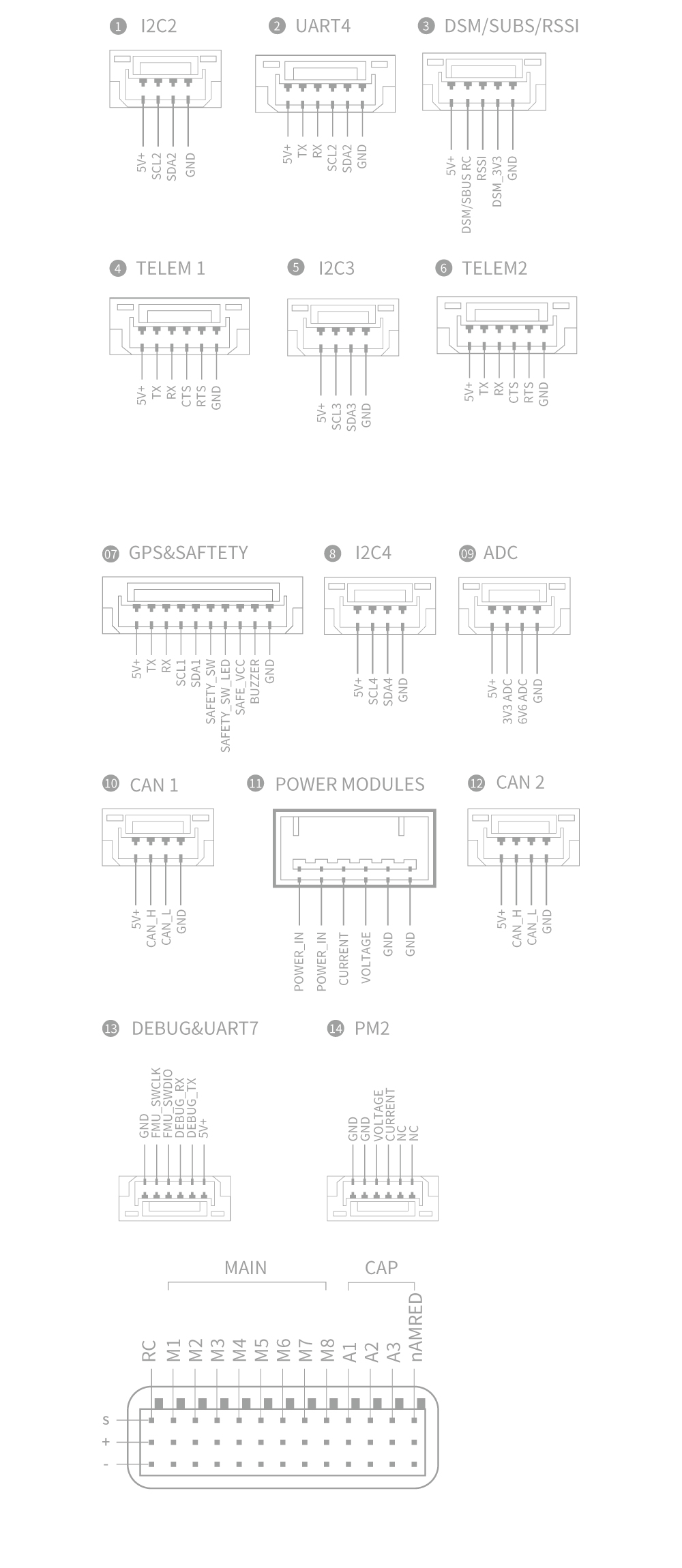

Interface Definition

Tips

If the diagram is unclear, please click to view the official V5 nano manual.

When running ArduPilot (Mission Planner) firmware:

Supports up to 11 PWM outputs (CAP1, CAP2, CAP3 act as servo9, servo10, servo11 respectively).

The DEBUG port functions as a general-purpose serial port.

The USB port serves as the DEBUG/console interface.

When running PX4 (QGroundControl) firmware:

The CAP interfaces are configured as PWM input ports.

The labelled DEBUG port functions as intended.

PX4 Firmware Compilation Command

make px4fmu-v5_default upload

ArduPilot Firmware Compilation Command

./waf configure --board CUAVv5Nano./waf copter --upload

Optional Hardware & Accessories

Similar to the V5+, the V5 NANO supports various accessories like Airspeed Sensors, Telemetry Radios, and Rangefinders. For complete compatibility lists, consult the multirotor and fixed-wing optional hardware pages in the respective firmware documentation.

Conclusion

The CUAV V5 series, comprising the fully featured V5+ and the compact V5 NANO, offers a powerful, flexible, and professional-grade solution for unmanned system development. Their born-from-collaboration design with the PX4 team guarantees optimal performance within the open-source ecosystem. Whether your project demands the extensive connectivity and rugged enclosure of the V5+ or the minimalist, weight-saving design of the V5 NANO, this series delivers the processing power, sensor suite, and firmware compatibility needed to push the boundaries of autonomy. By choosing a V5 controller, developers gain access to a mature hardware platform backed by the vast resources and communities of both PX4 and ArduPilot.

Procurement/Purchasing Communication

Laura

E-mail:Laura@cuav.net

WhatsApp:(+86)18078814327

Tina

E-mail:Tina@cuav.net

WhatsApp:(+86)18122367332